Facilities & Capabilities

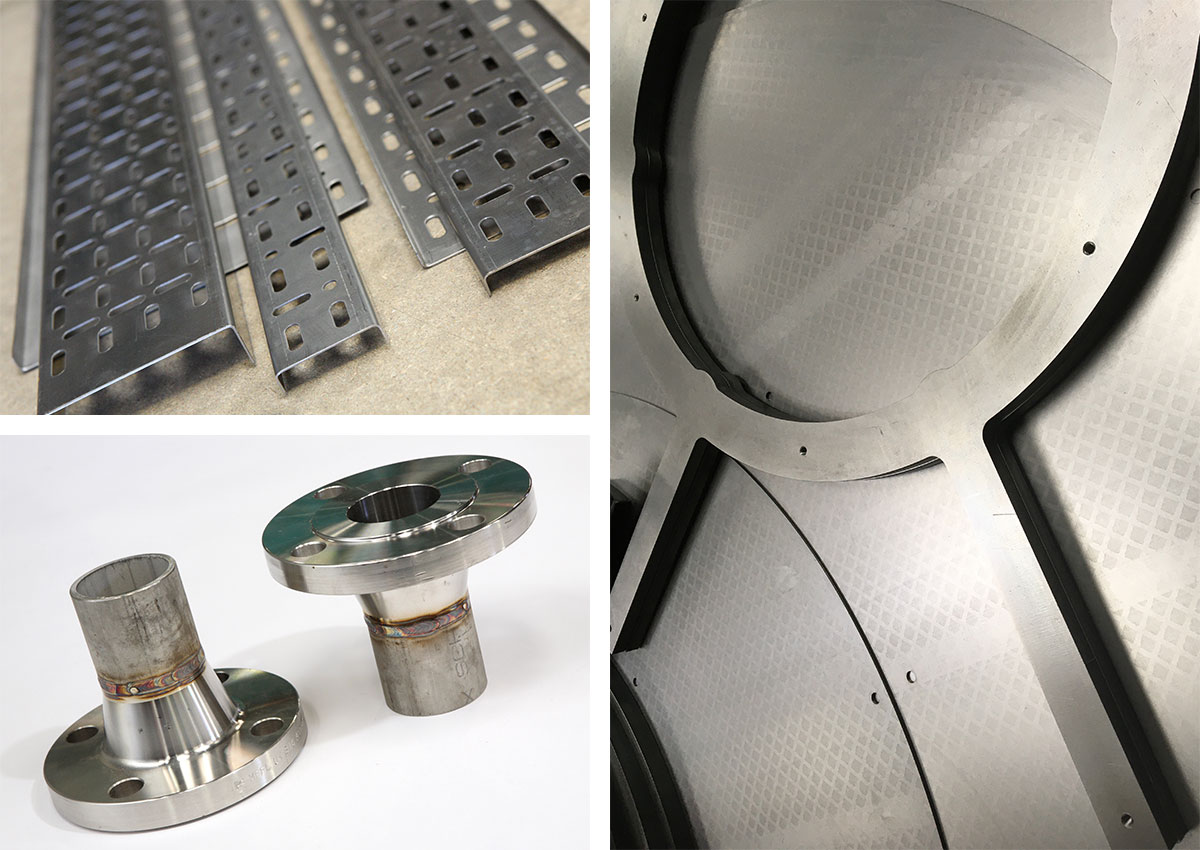

From our Lismac deburring machine to our TruLaser 3040 and our punches and presses to our TruBend 5230S, we really are in a fantastic position to cater for all different size and quantity requirements for a range of different industries.

Our metal fabrication jobs range from one-off products to batches of thousands and from the smallest components to those up to 13 metres long, made from stainless and carbon steel, our qualified team of experts can handle a wide range of specifications.

Don’t forget we’re ISO:9001 accredited plus our operatives receive all their training from the machine manufacturers directly so you know your metal fabrication needs are in safe hands.

Materials

We stock a large selection of raw materials that enables us to react immediately to customer requirements. Including:

- Exotics

- Duplex

- Super Duplex

- Mild Steel

- Stainless Steel

- Aluminium

Metal Fabrication

Both our stainless steel fabrication and mild steel fabrication are carried out on our state-of-the-art folding machines.

Recently, we welcomed a new addition to our machinery family, the TruBend 5230S. We’re proud to be the only provider in the area with this machine and this means we’re uniquely qualified to combine innovative technology within our metal fabrication with maximum precision to create quality products every time. The TruBend 5230S stand out quality is its outstanding productivity at every stage of the process. From programming and tool setup to the actual bending operation.

Our CNC Press Brake is capable of folding up to 4 metres in length. We’re extremely proud to be one of the largest Press Brake folders in the East of England.

Laser Cutting

With over 20 years of offline programming and planning experience, our CAD programmers will turn any idea into reality to produce accurate, quality laser cut components on time and on budget.

Our workshop is home to the state-of-the-art Trumpf TruLaser 3040 which combines the latest innovative technology and high powered laser. Its single cutting head for all sheet thicknesses offers increased speed and dynamics through linear drive technology and an integrated pallet changer for sheet exchange within seconds. As you know, time is money so we pass on these efficiency savings to our customers to make sure we not only offer a quality product but at competitive prices too.

Coded Welding

All of our coded welding is overseen and endorsed by TWI, The Welding Institute. So you know you’re getting the real deal.

We offer TIG and MIG welding services in a variety of materials so get in touch today for more information.

Machine Shop

Round House has a fully equipped machine shop that carries out both the machining required to create the fabrications that Round House is famous for and other machined components for our customers.

We have 2 Gate Mills and 2 Colchester lathes, as well as other machine tools across the larger workshop. Our machinists between them have over 40 years of experience, and quickly produce small production runs of parts.

Locally Outsourced Fabrication

Round House is a production partner for local businesses for volume parts at competitive prices.

Our customers rely on us for medium volume parts, generally between 10 – 100 off per month components. That being said, we often produce large quantity orders of up to 1000 off. Round House is able to hold strategic stock and guarantee delivery within 48 hours for any uncoated parts, 5 days for coated parts for our volume partners. This high quality production allows our customers to meet the demands of the fast moving economic environment.

Project Management

Whether you’re just starting out or are an established business, we’re here to help you with your fabrication requirements.

Our dedicated and experienced team are always on-hand to help you with your next project. Round House operate under a ‘no job too big or too small’ mentality, catering for large production runs as well as bespoke items. Whatever your project is, you can be sure that our account handlers will be with you every step of the way, ensuring the work is completed on-time and on-budget.